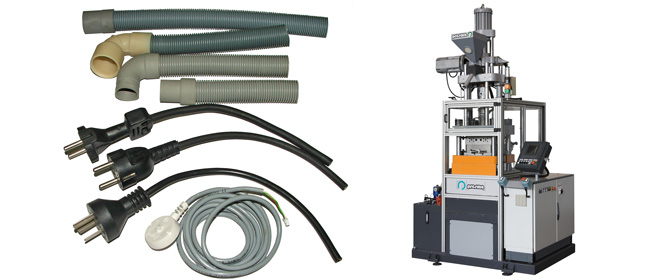

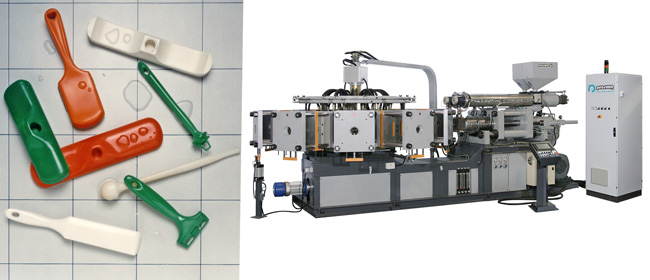

We offer wide range of PRESMA injection machines and production lines. Those includes facilities and treatment systems for the production of non-standard products in plastic injection moulding such as hangers (for hanging clothes), tools, brushes, handles, wheels, Shoes parts, heels, electric plugs including wires, synthetic corks stoppers for bottles of wine and alcohol.

PRESMA SpA Company established in 1937, when the three Canziani brothers built up the first manual press to process thermoplastic resins. Nowadays the Company is located in Torba di Gornate Olona (VA), 10 Km from the Milan-Malpensa airport and employs about 70 personnel on their 20.000 sqm site. Since the beginning of its activity Presma has been producing standard and multi-station injection moulding machines for processing thermoplastic materials either compact or expanded, co-injected, gas assisted and even re-cycled.

The production range covers over 100 different machine models, with clamping powers from 60 to 6000 kN, platens size up to 1.860×1.860 mm; quadrant machines with 1, 2 or 3 stations and rotary multi-station type from 2 to 18 stations, with both horizontal and vertical mould opening/ closing; injection units either by reciprocating screw or transfer system; standard, co-injection (sandwich structure) or multi-colour injection heads; working isles with one or more injection machines and robots for the moulding of multi-colours items; vertical clamping presses, with shuttle or rotary table, for moulds with two bottoms halves primarily for insert moulding. Recently Presma projected new machines for the moulding of thermoplastic stoppers (corks) for wine and spirits, for the over-moulding of pipe fittings, for injecting 35 Kg recycled PVC supports (for road signs) and for multi-colours multi-materials handles for household items.

Some machine models are specially designed for the production of shoe components as heels (with or without inserts), heel tops, wedges, soles, clogs, full plastic shoes and shoe lasts.

A brief description of our production ranges is listed here below:

ROTO E – E BIC: Machines with 4-5-6 and 8 stations rotary table suitable for injection moulding of Structural Foams (even recycled) and Co-Injection, with clamping power from 600 to 6000 kN;

ROTO G-HP-HSP-HSSP: Machines with 8, 10 and 18 stations rotary table suitable for the moulding of structural foamed materials with clamping power from 70 to 1200 kN;

ROTO HP-HSP-HSSP BIC: Machines with 5, 8 and 10 stations and clamping power from 300 to 1200 kN, suitable for the Co-Injection moulding;

CROSSLINKING: Rotary table machines with 10, 15 and 18 stations, designed to process cross-linked materials (Cross-linked Ethyl Vinyl Acetate)

TOP & TRIO: 2 or 3 stations rotary table presses with vertical clamping for the over-moulding on inserts

VE MIX: Injection moulding machines with vertical clamping and vertical injection;

IMQ: Injection moulding machines with 5, 6 or 8 stations rotary table, vertical clamping and vertical injection, designed for the over-moulding of fittings (on drain pipes) or electric plugs (on cords)

LOP: Injection moulding machines with 4, 8 or 10 stations rotary table with vertical clamping from 500 to 1500 kN clamping power and one or more vertical or horizontal injection units;

MODULO: Machines with 1, 2 or 3 stations, quadrant configuration, with mould vertical clamping from 600 to 1500 kN and horizontal injection unit;

GTV – GTS: Horizontal clamping presses with single or twin colours injection units

ROTO T2 – T4: Injection moulding machines with 96 or 192 single cavity moulds, designed for the production of plastic injected corks for wine and spirits

PRESMA news

Economical injection mini machine

The machine is used to inject small products, small series of products for lab and development departments.

Machine for manufacturing artificial cork stoppers

Those are used for bottles of wine and alcohol. Several models are available for various volume of production from 1,400 stoppers up to 7,500 stoppers per hour.

Injection machines for rubber and silicone

Those machines are used for production of products made of rubber or silicone The machines available as horizontal or vertical ones.